While our suppressors have stayed relatively the same from OPS INC to present day, there is one difference that can be observed, its coating. From how the coating was applied to the colors that were used, AE suppressors can sometimes look different from one another. Just like other aspects of AE, there is a history to the colors of the suppressors.

Processes

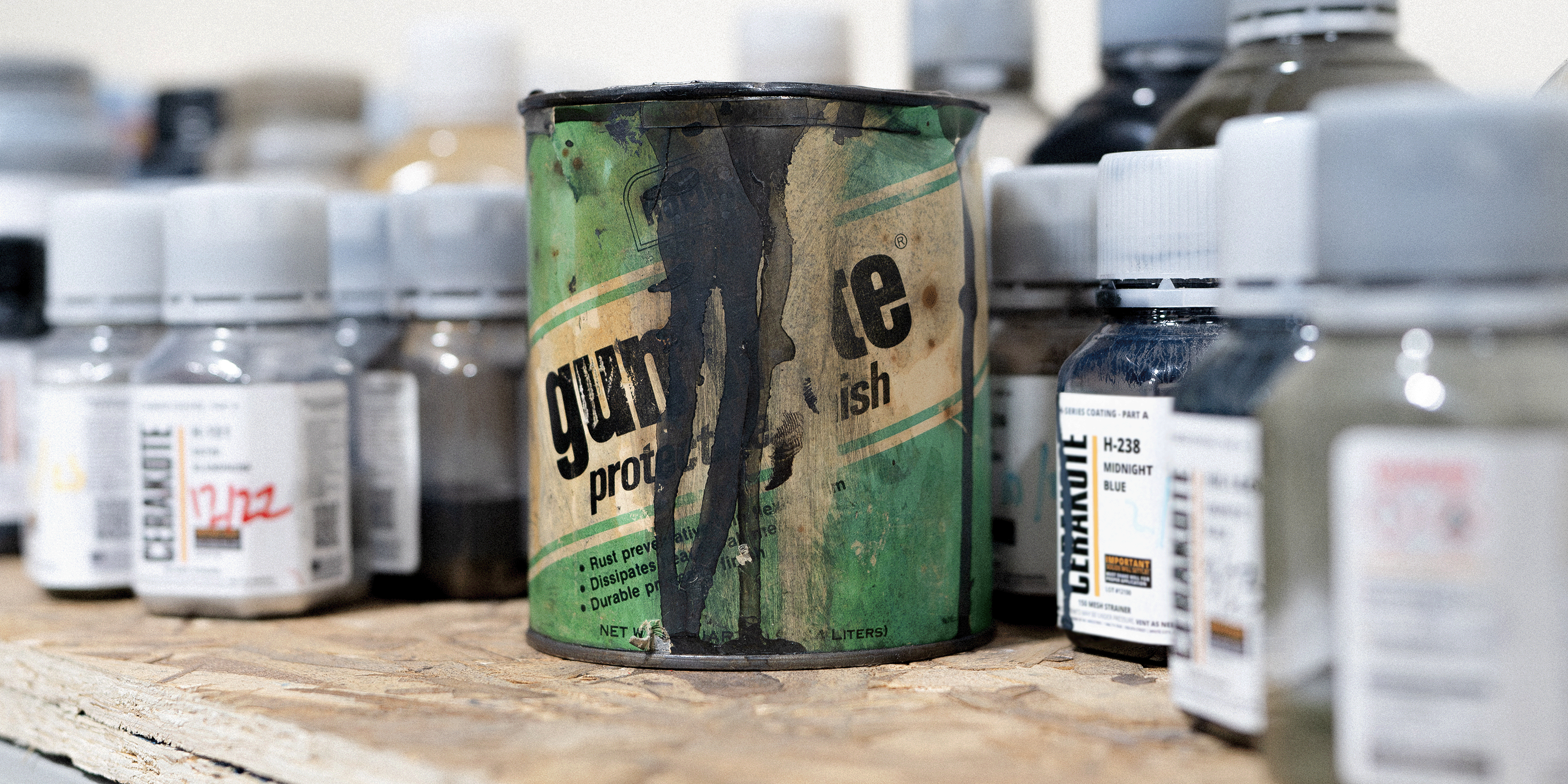

Gunkote: This is a thin film that is applied to the surface of the metal and then heat treated. The film is extremely thin which is why it was used on different weapon platforms such as rifles and mortars.

When Phil began to make suppressors he chose to go with Gunkote. It was a popular coating at the time for small arms and worked well on suppressors. The Gunkote Phil used was made by Kal-Gard and was grey with slight green undertones.

When Ron joined Ops Inc in 1993, Phil told him he had to paint the suppressors. Since Ron saw himself as pretty bad painter he refused. Instead of sending the suppressors out to get painted, which would increase the wait times, they decided to try a new method to keep the process in-house.

Black Oxide: Simply, this is a chemical conversion coating where metal is exposed to oxidizing salts within the black oxide solution. This causes a chemical reaction produces oxide from the metal giving the surface a matte black/grey look.

OPS INC was already using this process on small parts such as collars and brakes. So when they were looking for a new method to coat the suppressors they tested couple suppressors with black oxide and they ended up liking the matte grey/black look. Ron admits that black oxide wasn’t the best option for a finished product and worked better as a primer, but it worked well enough to handle the abuse OPS INC suppressors saw during military use. They would black oxide their suppressors until the ATF shut them down in the 2013/2014.

We still use this process with collars and brakes since the coating does not change the dimensions of the metal. This is because black oxide changes the color of the metals surface instead of layering a color on the metals surface. This is important when the collar needs to maintain its internal dimensions for proper fitment with the barrel.

Duracoat: Duracoat is more similar to traditional paint, making is extremely easy to apply. Unfortunently, Duracoat sits thicker, takes longer to cure, and is still less durable than Cerakote. Thus it never gained the popularity Cerakote has.

Ron approached Durakote to replicate the original Gunkote that was used by OPS INC in the 80s/90s. Ron provided them with original cans of Gunkote for them to sample the color. Since the paint had been sitting for over 20 years, it had separated and lost much of the original color. The green undertones were brought to the forefront and what Ron received was a brownish/green color.

Since Ron didn’t want to waste the paint that he paid for, he decided to use it. This is why you will see some of these suppressors in the wild.

Cerakote: This is another thin film coating that is applied to the surface of the metal and then heat treated in an oven. While it is slightly thicker than Gunkote, it is also much more durable and resistant to wear. It is still today the best method for coating suppressors and firearms.

As cerakote became one of the primary coating methods in the firearms industry, Ron made the transition to using it on suppressors. This is the coating method we still use today.

Colors

The process of how OPS/AE suppressors were coated gives a timeline of why certain suppressors look a certain way. So, what colors do we currently offer at AE?

Black: This is our most common color. There is nothing particularly noteworthy, its black Cerakote.

Flat Dark Earth: This is the first new color introduced to the AE catalog. Throughout AE history, many people have rattlecanned their rifles tan to match their combat environment and more recently more people are Cerakoting them tan. We wanted to provide an option for customers to have their suppressor match their rifle.

OPS Grey: Two years ago Ron sent us an original paint can of Kal-Gard Gunkote that was used on early AE suppressors. Since then, we have been testing multiple diffrent Cerakote mixes and comparing them with samples of the original Gunkote. Recently we made a mix that we were happy with and felt it matched the original color perfectly. We call this color OPS Grey. This is the primary color we will use for M4 suppressors.

Gunbroker Green: We have a mix of Cerakote to match the second batch of Gunkote Kal-Gard made for Ron. While this color will be more niche, it is a part of AE history and we want to provide it to the few people who want it. We call it Gunbroker Green because many suppressors from this generation ended up on Gunbroker.