Mounting, New Product

Allegheny Arms Gas Block

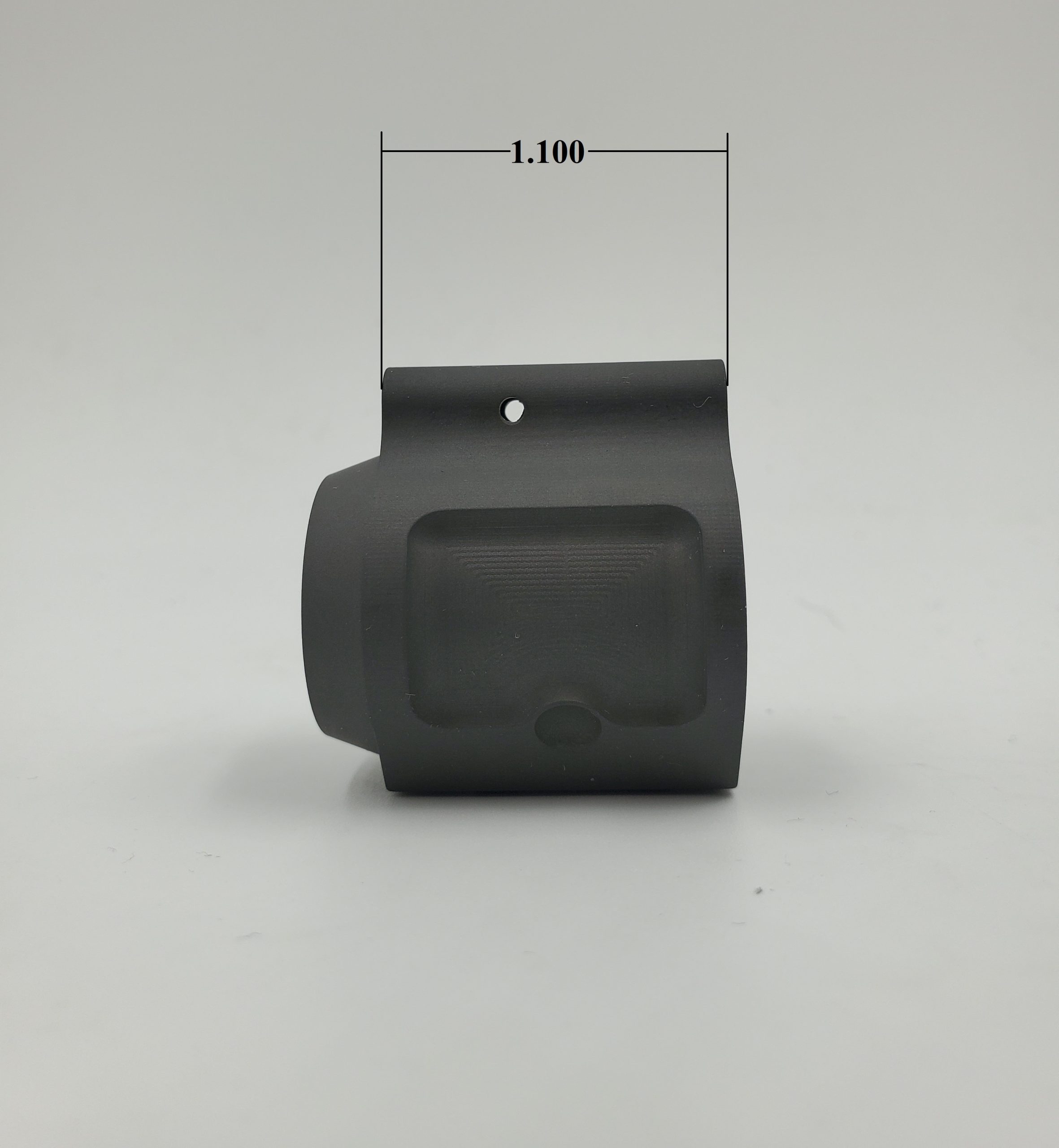

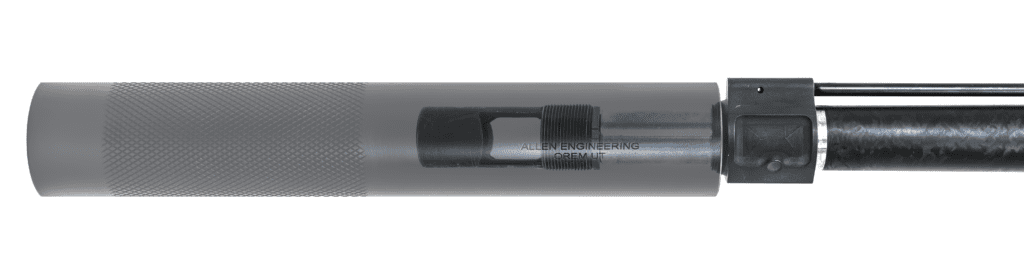

Introducing the Allegheny Arms Gas Block. This project simplifies the OPS/AE mounting system by combining the collar and gas block into one piece. This helps create the shortest mounting configuration possible with Allen Engineering suppressors. To purchase the AA Gas Block click here.

Josh Rowe of Allegheny Arms has been a long time advocate of Allen Engineering suppressors and has done a lot to support our growth. Allegheny Arms also does great gunsmithing and is very familiar with the OPS/AE mounting system. If you want AA to work on your rifle click here.

Are you wondering what specific gas system/rail/barrel length combo will work with your AE silencer? Unfortunately, current AE mounting solutions do not usually fit nicely within the standard gas/barrel lengths so with some exceptions, you’re probably going to have to send your barrel off to be cut to a custom length especially if you’re using one of our “A” series cans. For “B” series, though, the AA .880″ gas block in conjunction with a standard muzzle brake does allow drop-in mounting on certain common gas/barrel combos such as: 7.5″ pistol gas, 10.5″ carbine gas, 12.5″ mid gas, and 16″ rifle gas.

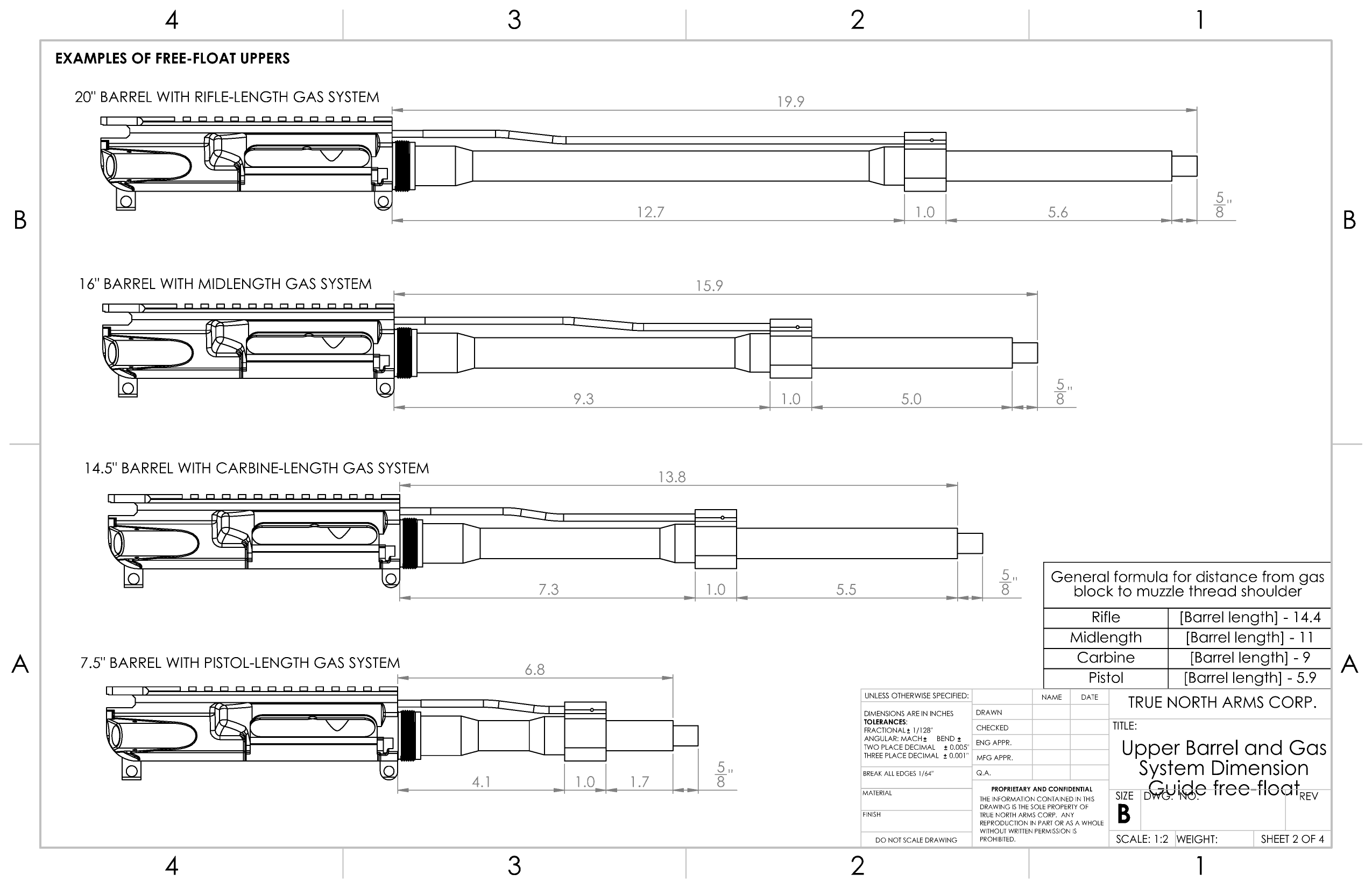

For virtually all other barrel length/gas combos, custom installation will be necessary. So with that in mind, for best fitment , we recommend you consider choosing your rail first by using the dimensions from the table below and this formula:

(length to gas block shoulder) + (AA gas block size) = longest possible rail

Once you’ve chosen your rail and gas block, you can determine your approximate minimum required barrel length using this formula:

(length to gas block shoulder) + (AA gas block size) + (.27″) + (Suppressor mount length) = minimum finished barrel length

A sample barrel length calculation might look like this: Carbine gas barrel (7.3″) + 1.100″ gas block + .27″ + A-mount suppressor (2.5″) = 11.17″

Once you’ve calculated the minimum finished barrel length you need, it’s time to go shopping for a pipe. But wait! You also need to remember that in order to guarantee correct fitment and silencer concentricity your smith will need to completely remove the original muzzle threads that usually measure out at .625″ so let’s add that to our formula to find the minimum production barrel length to shop for.

Carbine gas barrel (7.3″) + 1.100″ gas block + .27″ + A-mount suppressor (2.5″) + Original thread shank (.625) = 11.975

Now you can see that for this gas length/block/can combo you will need to start with AT LEAST a 12″ barrel to ensure your smith has plenty of barrel to work with. Remember that that is the MINIMUM and there is no real harm in buying longer. In this case specifically, it’s not uncommon for a 12″ carbine gas barrel to actually be more expensive than a 14.5″ or 16″ from the same manufacturer so don’t be afraid to go longer to save some cash!

We completely understand that this is a lot of math and that there are certainly other, easier options to suppress your rifles but just know that our team here at Allen Engineering are here to help. Also we fully recommend Allegheny Arms for all your gunsmithing needs. Their quality and service are exceptional.